Maintenance for chainsaw parts requires detailed know-how and more time to keep them running strong and cutting well. Maintaining a chainsaw prolongs its life span and reduces the risks of breakdown. Since chainsaws have proved to be one the most beneficial tools for the forestry and logging in industry, these metal tools use a metal bar of varying lengths to guide the toothed chain in a circular motion to cut through wood. The best way to get guidance or assistance is through the reader's manual.

However, specific experts are there to give the best advice to users. As following:

Sharpen The Chain

It is efficient to start with this step. A variety of maintenance for chainsaw parts tips needs to be accomplished with the chain off. First, it is good to check that the chainsaw is sharpened enough to start the cutting job. It increases efficiency and reduces the potential to trip into the emergency room as sharp chainsaws prevent dangerous kickbacks. But sharpening the chainsaw every time before using it is also not recommended. Over-sharped teeth can bite too deeply into the wood, which may cause the chainsaw to stall during work. Most chainsaw experts suggest to sharp the teeth when pressure needs to be applied while cutting. A good sharp chainsaw should work like a hot knife through butter.

Maintain The Bar Oiler And Levels

A chainsaw oiler contains an oil pump and oil holes. The pump transports the oil from the reservoir to the oil outlet holes in the guide bar. Most modern chainsaw oilers contain adjustment screw that mainly controls the oil flow to the guide bar. If the bar oiler works appropriately, it must distribute bar oil every time the throttle is squeezed. Many variables affect the oil flow, like temperature around. Anyhow the oil is pretty essential to the proper functioning of the chainsaw. Many new chainsaws include transparent windows into the oil tank making chainsaw maintenance easy to manage.

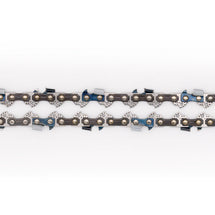

Chainsaw Tensioning

When expert advice suggests the maintenance for chainsaw parts, The chainsaw chain gets loose over time. Therefore, it is good to check the tension from time to time. A properly tensioned chain should have a little slack on the bottom but not too much to pull the drive links away from the guide bar. The drive links should always be engaged with the guide bar. It should not be over-tightened. An excessively tightened chain may result in breakage during the operation. Therefore there should be a little play in the chain while working. In addition, when storing the chainsaw away for a longer time, it is suitable to loosen the chainsaw. Also, cleaning the chain and oiling it is good before storing it.

Fuel & Oil Filters Replacement

It is good to use ethanol-free gas whenever it is possible. Most of the time, a chainsaw sits for months at a time in a garage or barn. A casual woodman will not use it more than once or twice a year; therefore, gasoline may go bad with less usage. So unless mixed with fuel stabilizer before properly storing, gasoline will oxidize and lose its ability to run the saw. It can even happen within three months or even less time. Therefore it is good to run the chainsaw empty before storing it and making sure to refuel it with fresh gas that has not yet exceeded the shelf life.

Verifying The Chain Break

It is efficient to check the chain break quite often as it represents the fundamental safety features of a chainsaw. The chain brake keeps kickbacks from ruining the day. So before gunning the chainsaw all the way, it is good to check that the chain brake effectively stops the chain from moving when it engages. Always set the chainsaw on the table or the ground and release the chain brake. Start the saw and squeeze the throttle to start the chain moving. Make sure the left hand is gripping the top handle securely. The hand should never let go of its grip.

Monthly maintenance

It is always nice to check the multi-vibration feature for wear and tear by ensuring they are not too soft and torn. Lubricating the clutch drum bearings weekly is reasonable to protect the clutch. Remove the chainsaw chain and inspect the bar by running the finger through the edge. Check the plugs by removing them and cleaning them. Then clean the chainsaw flywheel fins and ensure the recoil spring works fine. Clean the carburetor alongside the airbox. Also, it is safe to check the chainsaw brake band every month. There should be no breakage or weak points in the chain breaks. If there is any breakage, it should be replaced. Checking the clutch monthly is also a good choice.

Conclusion

No doubt it doesn't seem easy keeping the chainsaws maintained at first. However, proper maintenance isn't that difficult. In fact, it is pretty easy. Every chainsaw is different, but they almost work the same. A chainsaw is not only an investment, but it is a hazardous machine a person holds in his hands. Therefore, having a well-maintained chainsaw helps in better functioning and keeps the user safe and sound.